There have been a myriad of posts over the years asking for help with getting a bicycle’s rear derailleur to index and shift correctly when installed on a direct drive trainer.

The conventional wisdom is to either use the cable barrel adjuster to re-index the rear derailleur, add/remove spacers behind the cassette to better match the spacing on the bike wheel, or some combination of both.

There’s another way.

⚠️WARNING

The shims (spacers) used here for tuning cassette offset from the dropout face were not originally designed for this purpose. Rather, they’re for taking up excess space on a freehub body when using fewer cogs than the freehub was designed to accommodate.

Installing more or thicker shims than were needed for their original purpose may result in insufficient threads for the lockring to secure the cassette. Tightening a lockring with only a couple of threads engaged can strip the threads on the freehub body.

You should ensure there is sufficient thread engagement between lockring and freehub body if attempting this solution.

This process assumes your bike is in good working order and the derailleur hanger is straight. Derailleur alignment is often overlooked by bike shops when delivering customer bikes and alignment tools (like the Park Tool DAG-3 34) aren’t commonly owned by the home mechanic. If in doubt, please bring your bike to a reputable bike shop to check derailleur alignment before attempting to tune your drivetrain.

Before You Begin

- Chains and cassettes should have similar levels of wear or they will tend not to shift well, may skip, and be overly noisy. Provided your bike is in good working order (per the assumption in the section above), the sure-fire way to eliminate this as a source of problems is to transfer the cassette from your bicycle to your trainer.

- Alternately, if your bike chain has zero wear, putting a brand new cassette on the trainer that is identical to what’s already there (number of cogs, number of teeth per cog, same brand and spacing) effectively matches them. (If you have problems, though, go back to step 1.)

- You will need some basic bicycle tools such as a cassette lockring tool and chain whip. I’m going to link to some Park Tools, specifically the least expensive versions you need.

- Additionally, the process below requires a digital caliper with a depth gauge, and you will likely need a set of cassette spacers of varying thickness (unless you happen to get lucky and have one on hand of the perfect thickness).

Matching Cassette to Dropout Spacing

Here we go!

- Remove your rear wheel from the bicycle and lay it on a surface you don’t mind getting greasy. (I like a yoga mat in my flat for this type of work.)

- Take the digital caliper out and zero it. (It should read zero when closed.)

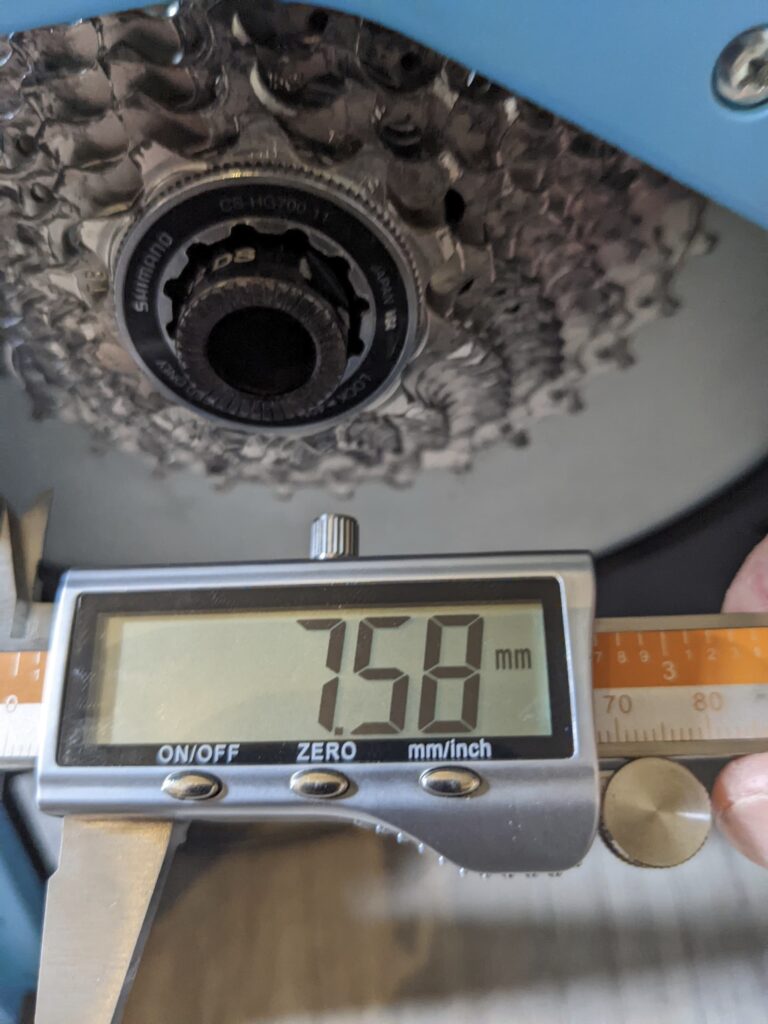

- Use the depth probe end to measure the distance between the cassette lockring and the hub axle. NOTE: if this is a QR axle type hub, you want the wide part of the axle which contacts the drop-out, not the narrow section that sticks out farther. Ensure you’ve aligned the caliper with the axle as best as possible – misalignment will throw this measurement off. CAVEAT: the thickness of the cassette lockrings on your bike and trainer must match for this to work. If they don’t, you’ll need to account for this in your calculations.

- Write the above measurement down. This is the distance between your cassette and the drop-out on the bicycle. We’re aiming for the exact same distance on the trainer so your rear derailleur “sees” the trainer as being identical to the bike vis-a-vis shifting.

- Repeat step 3 above but this time on the trainer. Write this number down. If the two numbers are the same, great! Install the bike and test it out.

- If the trainer and bike cassette to dropout spacing don’t match, note the difference to the closest 0.1mm increment.

- Remove the cassette from the trainer. Take note of any spacers already installed and how thick they are. (The caliper jaws are ideal for this.)

- If the cassette to dropout spacing on trainer is less than that on the bike wheel, you need to remove spacers or install a thinner one. If the cassette to dropout spacing on trainer is greater than that of the bike wheel, you need to add spacers.

- Once you’ve added/removed spacers to match wheel spacing, reinstall the cassette, install the bike and give it a test ride.

Comment

My “trainer bike” gear indexing was already pretty close to matching between road and trainer use. Until I figured the above out, I was fine just spinning the rear derailleur barrel adjuster when moving the bike on and off the trainer.

However, adding a single 1.5mm spacer brought the two into perfect alignment (within 0.1mm). Zero adjustments necessary between the two! To me, this is the more elegant solution.

Measuring the Wheel

Tool & Parts

I’m not endorsing any specific brand, merely providing examples of functional tools. I appreciate the quality, availability, and warranty of Park Tool but there many other respectable brands such as Shimano’s “Pro Tools” line, Pedro’s, and (money-no-object) Abbey Bike Tools.

- Park Tool HCW-16 – combination chain whip and pedal wrench

- Park Tool FR-5.2 cassette lockring tool (you’ll need an adjustable wrench to use this)

- Generic digital calipers

- Drivetrain spacers by Problem Solvers 60 and WheelsMfg

- Park Tool CC-4 5 chain wear tool (not specific to this guide, a chain wear tool is just a good idea to have on hand. Measure your chain regularly for wear and replace earlier than later – a worn chain will result in poor shifting and chew through cassettes and chainrings. If you’re diligent, other drivetrain components can last through several chains)

Questions or Comments?

Share below!