Part one of this two-part article highlighted how I connected with Nopinz to utilise their “Club Shop” feature, getting my virtual Zwift jersey designed and available to all my “Mountain Massif” club members. Here in part 2 we’ll look at the next step, which is getting the garments manufactured and distributed.

One thing to note regarding Nopinz is that it is a solely British-owned and operated manufacturing company based in Barnstable, Devon, UK. In today’s global economy, it is less and less common to see a product designed and manufactured on the same premises. Nopinz are bucking this trend and by keeping the entire process in-house are able to exert a high degree of quality and process control. This helps optimise all steps of the production process, ensuring the minimisation of waste, which ultimately helps keep the costs of the items down.

To produce my jersey, there were a number of complex but interesting processes that took place, which will be outlined. It’s worth noting that the “Club Shop” feature is proving popular and consequently, due to the volume of orders, Nopinz has a 40 working day lead time from when the order is placed to when it is manufactured (although they aim to send the completed order before that).

Setup

Each item, whether a jersey or set of bib shorts, is individually printed. This first step in the manufacturing process is called “setting up the flats.”

This means that the garment’s design is deconstructed into its key components. Effectively, the different panels that comprise the garments are split out and laid out to optimise the use of the different fabrics (for example, with a jersey, the arms are constructed from a different material to the front and rear panel). This creates a template, called the “flat template.” The “flat template” is created for any new design and used in the production of future items.

These templates are compiled to create what is called a “print run.”

Historically, these templates were compiled manually, like a giant jigsaw puzzle, to optimise the use of the fabric. However, this has been recently automated, refining the process and thus reducing production lead times through the removal of a manual step. Perhaps most importantly this maximises the use of the fabric, ensuring very little is wasted.

Printing and Pressing

The next step in the process involves printing the design on a special form of paper called “textile transfer paper.” This paper is then pressed to the fabric, and under intense heat and pressure, the designs are transferred to the fabric via giant rollers. This is called “dye sublimation.”

The fabric specifically-manufactured fabrics are stored in-house.

Cutting and Picking

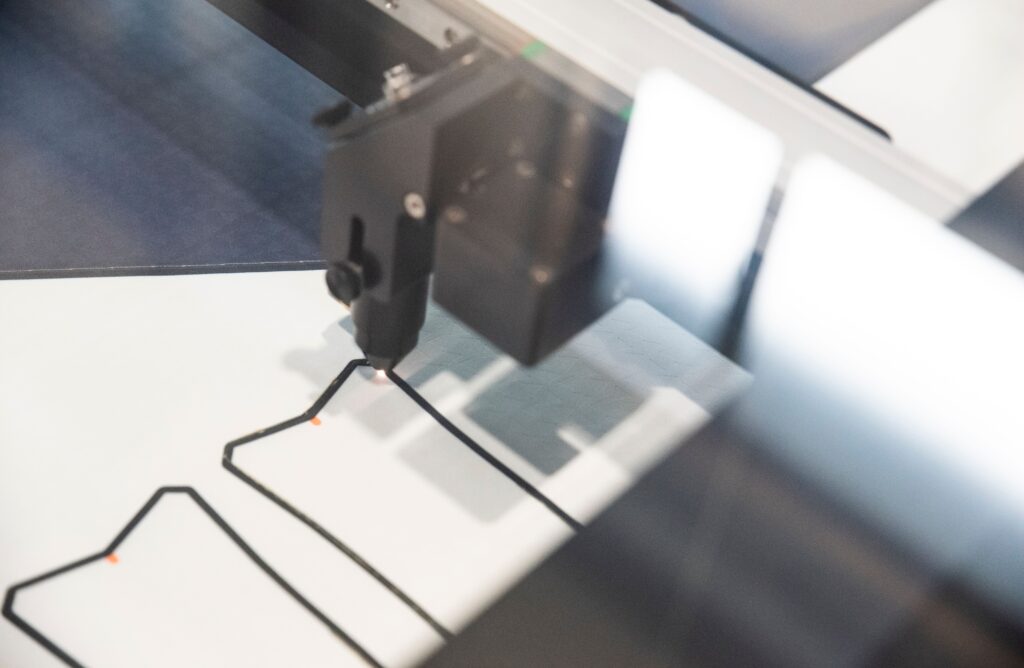

The components are then cut from the fabric using a laser. The laser makes precise cuts along predetermined black markings and the individual panels are picked by the staff and bagged. Any discarded fabric is collected and recycled.

The “picking” process is vital because not all print runs will have all the components of the garment. For example, the arm panels for a jersey will most likely be in a different print run to the front and back panels and consequently it is the job of the “Pickers” to collect parts so they can be passed to the Machinists to be transformed into the garment.

In addition, at this point the silicone is applied to relevant panels such as leg grippers and arm grippers.

Construction

The Machinists then receive the bag of all of necessary parts to construct the garment and undertake the task in its entirety. This ensures a sense of completeness, as the Machinist gets to see the final product, then sign a card to let the end user know who produced the item.

I caught up with Jenifer, a Machinist who has worked for Nopinz for 6 years and asked her about the finer details of constructing a jersey. Jenifer explained that a “normal jersey takes roughly an hour to make from start to finish.” Similarly, a “Pro 1 skinsuit can be made and finished in an hour but a Flow suit can take between an hour and a half to two hours.”

As you would imagine the more complex designs take longer; however, the difference in production times was not as diverse as I thought. Despite the Flow suits taking longer, she noted, “I enjoy making the Flow suits and tri-belts the most because they have more detailing and have a nice ‘finished’ look. I enjoy making tri-belts as it is something different to make as an accessory to full kits.”

Jenifer explained that the most difficult part of the production process is “matching a detailed and intricate design over seams and over zips so that it isn’t distorted and looks how it is meant to look.” She commented that her least favourite item to make was the warm-up leggings because “you have to cover stitch the waistband and it is quite fiddly and can be frustrating if it doesn’t quite sit right when on.”

Distribution

Following the construction of the garment, the items gets packed in their own branded bags and dispatched. Nopinz offers a global shipping programme so your items will be shipped wherever you are located, making this ideal if you have a global, virtual club.

Wrapping It Up

When my Nopinz parcel arrived, I was filled with anticipation! It’s always nice to receive new cycling kit, but when it’s something that you have been personally involved with, that sense of expectancy is heightened.

I was not disappointed when I finally opened the package and held the jersey before me. The design and construction is such that it would not look out of place within the pro peloton. The colours were clear and defined, the logos and branding, sharp. This was definitely something to be proud of, with each logo part of the history of the “Mountain Massif” event series and now Zwift club (which can be joined by clicking here).

In terms of the jersey, I opted for the Superlight eco jersey. It has a nice comfortable fit, the zipper is robust and easy to use, and its three rear pockets are big enough to carry your essentials. The rear pockets are edged with reflective material, which is a very nice feature for two reasons. Firstly, safety: this being a black jersey, the reflective strip may help keep me visible in overcast conditions. Secondly, being grey, it ties in with the design of the jersey.

Another nice detail is the waistband. This is rubber and has been manufactured to ensure the jersey doesn’t rise up your back when you move positions, notably when out of the saddle and climbing.

Equally, the bib shorts were a nice fit, with a good level of padding in the shorts and comfortable elastic shoulder straps.

In terms of the quality of the garment, it’s second to none, a topic that I discussed with former multiple-time British time trial champion Alex Dowsett, who since retiring from professional cycling is working with Nopinz. Alex explained:

“The Nopinz kit is in the full performance bracket of sporting equipment available to cyclists. The Flow suit is highly competitive and stacks up in the wind tunnel, which I tested in an unbiased capacity. And the Road skinsuit was used when I won Stages in the 2020 Giro.”

The reason for the high quality of Nopinz’ product is, as Alex summarised, that “Nopinz has the entire ecosystem correct, they use the correct materials for the job, the construction of the garments is correct, with high attention to detail in all aspects, including their ‘Custom fit’ kit which really makes a difference in the wind tunnel and in a race, allowing you to squeeze out an extra bit of speed.” Alex noted that “no performance products are made off-site, allowing for efficiency with the construction of the garments and a high degree of quality control.”

Talking of quality, Alex explained that upon a recent visit to the factory, it was special to see garments that would be used in the Tour de France being manufactured next to club kit, showing that whether you are a small club or a team competing at an international level, you have access to the same quality items that historically have been exclusively available only to the professionals. Alex also mentioned that “the Nopinz team are able to accommodate most requests due to the bespoke skills within the company.”

The bespoke skills Alex noted were evident in the creation of my jersey, an overall process that I could summarize as “fun.” I have enjoyed working with Nopinz and I am impressed by the output – the jersey arrived within their 40 working day timeframe to a quality that exceeded my expectations. Furthermore, their vast range of products available to club members is incredible and I will be putting additional orders in for items such as t-shirts and hats. (The full range of items can be viewed here.)

If you are part of cycling club, whether virtual or in real life, and you want some new and professionally manufactured products, then it’s certainly worth connecting with Nopinz by following this link. What I like is that it creates this bridge from the virtual cycling world that we all enjoy and are passionate about, to something physical. That is special. The “Club Shop” enables people anywhere in the world to purchase kit and have that physical connection to the club. Nopinz have truly helped me transcend from the virtual to the physical world.

This leaves me wanting to acknowledge those that have helped transform the initial concept of a club jersey into reality. These include Jon Geddes, Dan O’Shea, Neil Allen, Emily Ormond, and the Nopinz Team.